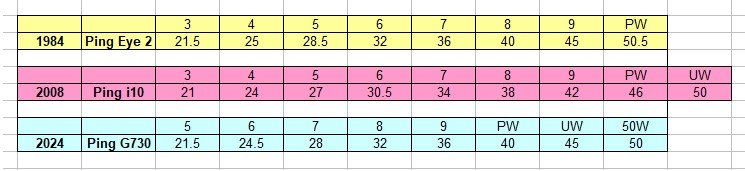

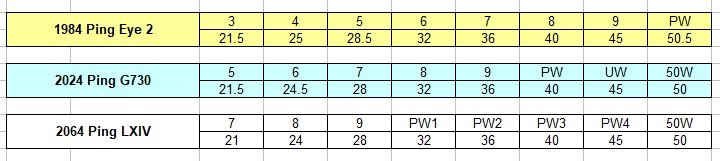

It shows how, despite the annual creativity of their marketing departments butchering of the word 'tech', the sum total of 40 years 'research' into club 'development' 'technologies' and 'progress' has been to forge or cast a 7 instead of a 5 onto a 28° iron.

Impressive though. From the marketing guys and gals.

Impressive though. From the marketing guys and gals.